The local open lab sent out a call for ideas to run workshops over the lead up to Christmas. I thought of a Christmas tree with candlelight LEDs. I needed to know what was involved in making such a model before I could conduct a workshop. In this post I describe the that approach that I took and the improvements I came up with as a a result of trying it out first hand.

The Idea

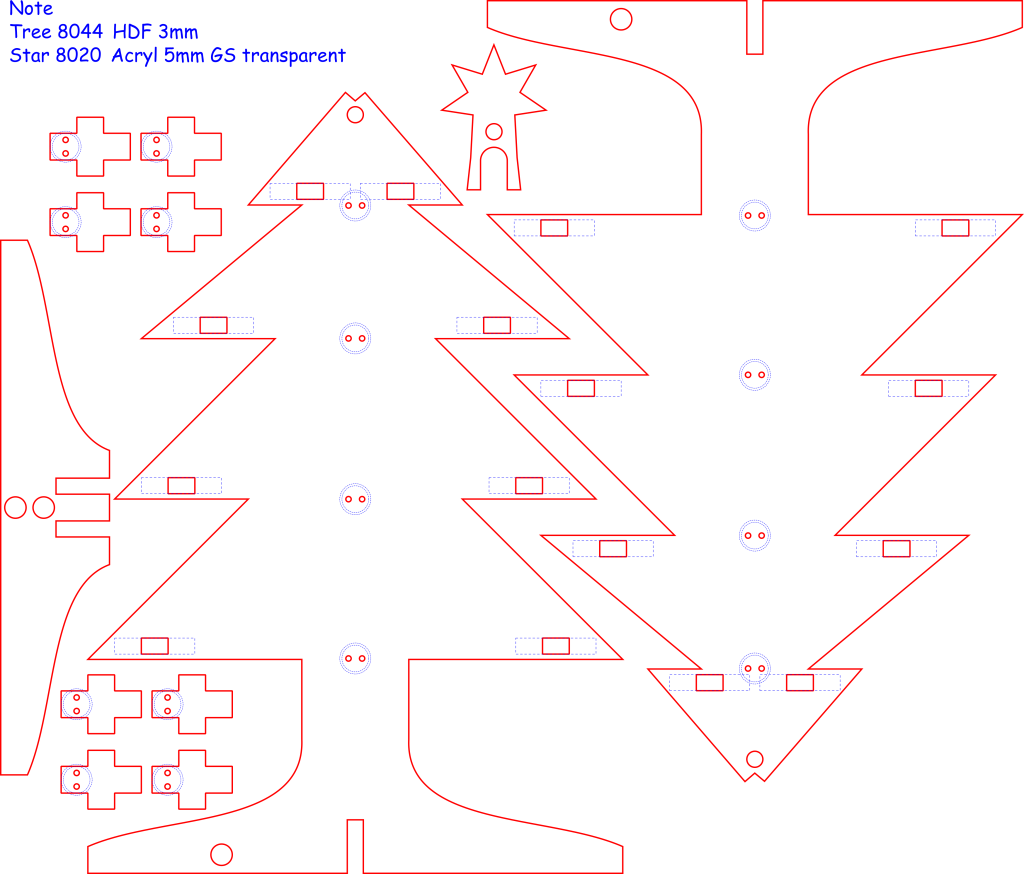

The open lab is only new, as is my involvement with such a workshop, so when the call was made for ideas, I wanted to contribute. The first idea that came to mind was a Christmas tree, so I sketched up a simple tree shape in Inkscape. The idea was to have this cut out in High Density Fibreboard (HDF) using a laser cutter. This would form a base that could be decorated with self-flickering LEDs. The idea was not well thought out as I had not really made anything like that before. So to propose this as a topic of a workshop, I figured I needed to understand more about what is involved in the project itself.

The first thing I needed to do was to finalise a design. I did not want it to be too large as this was to be a prototype, but it needed to be easy to wire in the LEDs. I figured 150mm x 100mm would be a good start.

Final Design

LED support and stability

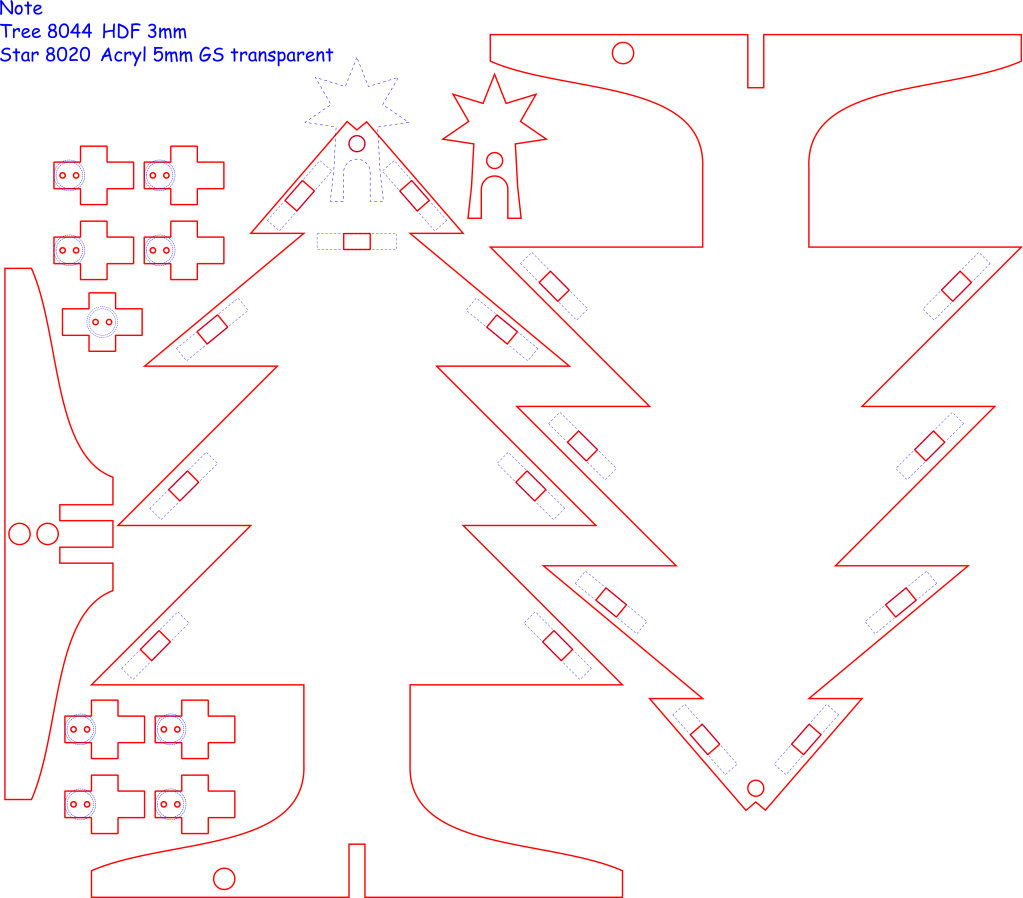

The initial sketch was OK but it lacked stability. I also tried to imagine how I would set the LEDs in place. One thought was with hot glue. Thinking about this I came up with the idea of creating small spacers that would fit between the two tree plates and also have holes for the LEDs. That way I believed that the wiring could be made easier by having the LED fixed in their location and not moving about.

I also came up with the idea of a star shape made from clear or smoked acrylic with a notch for a clear LED. The idea is that it would have the flickering of the candle and a star with a solid glow.

Assembly

The assembly was not without difficulties. The size of the model meant it was quite fidgety to wrap and solder the wires. I also needed to consider current limiting resistors since the LEDs don’t include any. Where possible I had had to also add some heat shrink to avoid any shorts. The lack of room meant I dropped the idea of having LEDs mounted in the centre of the tree. This would have added more expense and for the size of the model would have been excessive.

The model can be left rustic i.e. no decoration at all or spruced up a bit. In Fig 4. I painted one side only as an example and used FIMO to create the baubles and candy canes.

Changes – making it simpler to work with

The practice of making a sample tree helped a lot to understand the process for creating such a project, not to mention the practice using the laser cutter. I have some definite improvement ideas. The first idea I had was to make the model larger. While that would help, there are some other changes to the design that would make a difference without the need for making the model larger.

Improvements

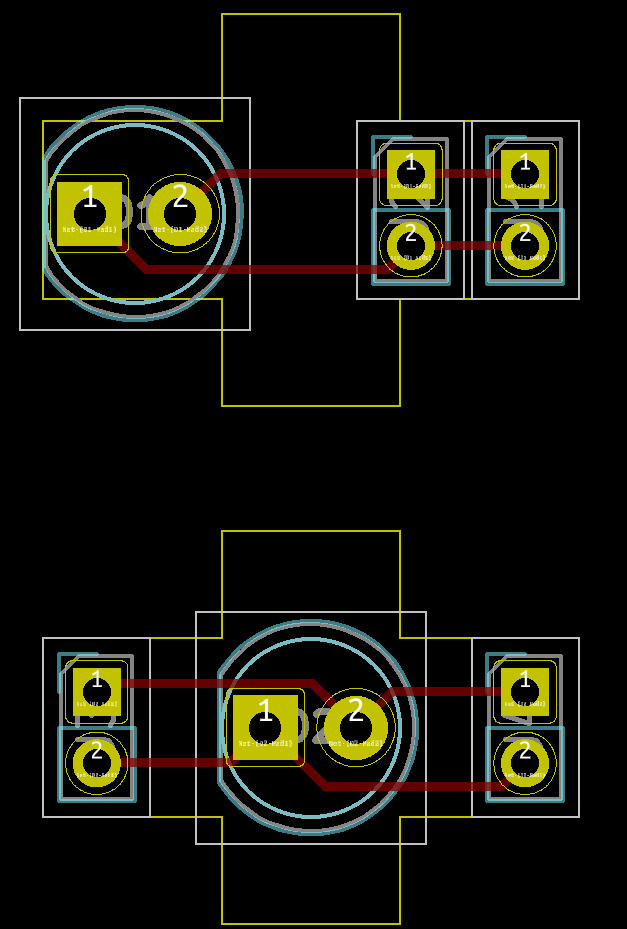

- Rotate the LEDs 90°. That way the anode and cathode would be placed neatly side by side. Part of the problem with the wiring was the they were one behind the other and in such a small space was hard to work with.

- Move the spacers higher to the upper part of the branch. The position of the spacers was too low. I did not consider the leads coming through and the wires soldered to them. This means that the wiring shows through the underneath of the branches. Interestingly, this is not obvious when the viewer is at a higher angle to the placement of the three.

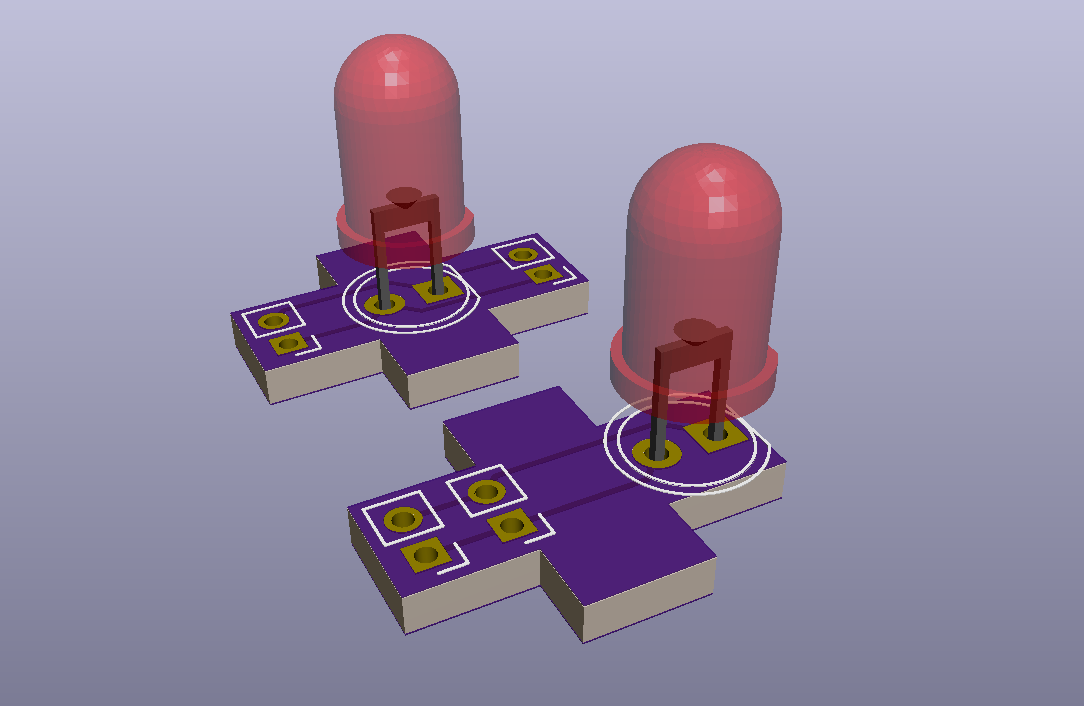

- Use small PCBs for the spacers instead of laser cut HDF. The LED would be mounted to the board. The length of the leads could be better controlled and connector pads for the wiring means that there is no need for heat shrink and there is no risk of shorts. Though this would be the most expensive option.

Repository Tannenbaum_2021